Man’s dominance over metal–the bending, shaping and forging of this seemingly rigid and impenetrable material–was established more than 6,000 years ago. And while tools and techniques improve, the noble craft remains, at its heart, much as it was when those ancient people first brought civilization into a new age.

Springs metalsmith James DeMartis is keenly aware of this antediluvian legacy when he sets his forge ablaze and puts hammer to red-hot steel, but he also embraces the future and the now–the precise, the machined and the fabricated. It’s an unusual gift and the reason he’s sought after for everything from Hollywood period and fantasy props to space age kitchen designs in the Hamptons’ finest luxury homes.

“You never know what comes through the door,” DeMartis says, explaining that work is never dull at his studio on Springs Fireplace Road in East Hampton.

Since opening his own shop there in 2001, DeMartis has earned a sterling reputation for his artistry and ability to make just about anything a client can imagine. Today he works with a long list of interior designers, architects, artists, and businesses on projects that truly test the scope of his mastery. And he always delivers.

“My focus as a creative person morphed from purely sculpture to sculptural furniture,” DeMartis says, pointing out that he learned to make all manner of functional metal objects along the way.

Born in Brooklyn and raised in Westchester by artistic parents–his father was a painter and his mother is a passionate art lover and collector–DeMartis first came to the East End after answering an ad to work with artist Nova Mihai Popa. “I never heard of the Hamptons before,” he says, recalling those early years creating alongside Popa, who was just starting to make sculptures at what eventually became Nova’s Ark Project in Bridgehampton.

In college, DeMartis learned to weld, cutting metal with a torch and putting pieces together, but he only began working with hot metal and a forge in the Hamptons. Following his time with Popa, DeMartis spent seven years assisting ironworker John Battle, before eventually starting his own operation.

“It was fairly immediate, my enjoyment of the process and metalworking,” DeMartis says, adding, “Art always came naturally…but I never thought of it as a career pursuit.”

The metalworker makes plenty of time for creating sculpture and the artistic furniture he’s passionate about, such as his melted iron and wood or cast glass “Stalactite” tables, but he also gets deep satisfaction from making a wide array of custom pieces and commissions. “I like both,” DeMartis says. “I do like the collaborative process and working with other people–there’s a challenge to that I enjoy.”

Repairs, commissioned projects, and personal designs change with great regularity in the shop, DeMartis explains, noting that he could have a nineteenth century cannon lined up next to a stainless steel mirror, a complicated wrought iron gate, and even some fanciful tool or weapon for a character in a film production. “That’s what keeps it interesting for me,” he says.

Rattling off a list of highlights and recent projects, DeMartis describes making a laboratory for Prospero’s cave in Julie Taymor’s The Tempest, custom stainless steel kitchen cabinets, andirons and fireplace accessories, architectural hardware, decorative gates, indoor and outdoor railings, custom lighting, and a stove and weapons for Darren Aronofsky’s epic film Noah, starring Russell Crowe (DeMartis even appeared in the film as a blacksmith).

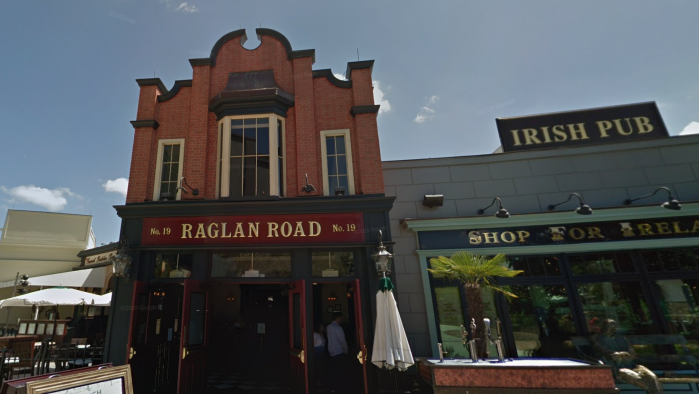

He’s done work for several well-heeled restaurants, including Eleven Madison Park in Manhattan, and 1770 House, CittaNuova, Rowdy Hall and Nick & Toni’s in East Hampton. DeMartis is also making items for world famous jeweler David Yurman’s boutiques.

“That’s what separates me from other businesses and metal tradespeople,” DeMartis says, referring to his ability to tackle so many different styles of metalwork, be it artistic, hand-hammered traditional, or precise, machined fabrications. One recent set of decorative gates featuring expressive dog figures was created using a host of techniques and processes, including 3-D scanning and printing, casting, welding, sandblasting, forge work and more.

Of course DeMartis can’t do it all by himself. More than 15 years after opening, he now employs assistants for creation and administration.

“I’m very much a team now,” he says. “It’s just how the business evolved,” DeMartis continues. “I never set out to be a small business owner–I just wanted to make things, but before you know it you have five employees and a nice client list.”

Call 631-329-2966 or visit jamesdemartis.com for more info.