Summer may be over, but one whiff of the right smell and you can be transported right back to a warm beach. A certain aroma can be reminiscent of a fond memory. Whether it’s the salty air or the scent of a fire pit, certain smells evoke a familiar Hamptons feeling even if you’ve taken off to Palm Beach for the winter.

Montauk Candle Company, a family-owned business born out of Montauk, is accomplishing just that. They carefully craft aromatic batches and hand-pour each natural soy candle selling them not only on the East End of Long Island but to customers all over the country.

“We knew that people wanted to take a slice of Montauk home,” says Michael Kirkwood of Montauk Candle Co., which was founded in 2014, and this is one way, he adds, to do that inexpensively.

About 15 years ago, Kirkwood and his wife, Kathleen, started getting interested in candles. They found candles online to raise money for their children’s high school sports team. “The problem was that they were charging me retail prices for the candles and they weren’t the greatest quality, but there was nothing I could do about it. So we sold the candles, we made the money on that, but then I started thinking, ‘Hey, this went over so well, let’s try it again.’ We did it another time and then we said, ‘OK, how can we turn this into something that we can do together?’”

They started by doing their research online, by not only reading up on the subject but also watching YouTube videos. “We bought our first set of wax, our first set of wicks, our first set of containers, and we just started experimenting with a basic wax melter,” he recalls.

Kirkwood, who runs an advertising agency, knew that if they wanted to have their own label, the key to success was to associate it with a destination — a recognizable place.

The family has had a home in Montauk since 1980. His father, Eugene, has been going out to Montauk since he was a child in the 1940s and began renting 30 years later, “when Montauk was Montauk before it was ‘discovered,’” his son says.

They decided to name each candle after famed and family-favorite landmarks.

There’s Lake Montauk Lavender; Ditch Plains Driftwood with cedar, pine and sandalwood; Gin Beach Ginger Lily with top notes of ginger and saffron, middle notes of cardamom and ginger flower, and a base of sandalwood and musk. Fort Pond Bay Breeze features bergamot, bamboo and violet; Montauk Point Sea Pepper with a note profile of grapefruit, orange, sage, lavender, tonka bean, amber and oakmoss.

While they have taken creative license with some names and their corresponding smells, many are true to form. The notes of clove and saffron, mixed with sandalwood, incense and clove, and a base of smoke, patchouli and amber work perfectly for the Beach Bonfire candle. “The only way to end a summer night is with a beach bonfire on Ditch Plains Beach,” the description reads. “This scent brings you to those warm summer nights surrounded by good people, good vibes and good times.”

They have also expanded the names to other areas of the Hamptons, such as Sag Harbor.

Seasonal candles have followed. Christmas Hearth is perfect for the upcoming season, offering “a classic holiday fragrance that tells the story of a cozy holiday night spent sipping wine in front of the fireplace.” It combines “orange spice notes from the kitchen, fir and pine notes from the Christmas tree, and an earthy smokiness from the fireplace.”

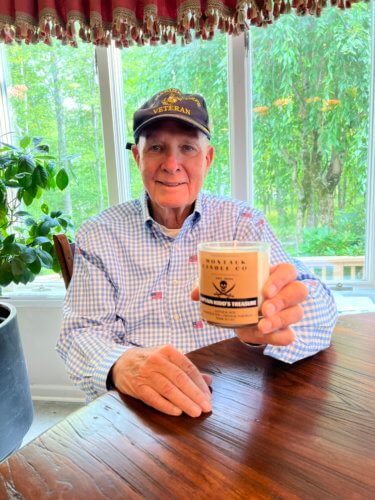

Michael Kirkwood is in charge of production, while his wife serves as the president of the company, and his father, Eugene, a veteran who spent more than 50 years in the financial industry, is the head of sales but is considered the “master craftsman” of the family, since he makes the candles with Michael.

He certainly never thought he would be selling candles, many times shop to shop — especially at his age, though it has come naturally.

“I went in financial business, from 1967 on, until about a year ago, but when I went to college — I went to St. John’s University in Jamaica, New York, and I met a guy who was a Bible salesman and he sold Bibles door to door, and he said, ‘Gene, would you wanna sell?’” he recalls. As a Bible salesman for three and a half years, he would knock on doors and go to churches and sell them following Mass on Sundays. “I got a very good feel about working with the public and working with people doing that,” he says. “So it was natural for me to walk in the store with a candle.

“I just started knocking on doors,” Eugene adds. It didn’t matter the store — florists, general stores, tchotchke stores and even bake shops. “I always wear my Marine Corps hat — I spent time in the United States Marine Corps going back in the ’60s. So, I felt maybe it’s made in the USA, it’s all USA and I sell USA. That’s how it started and it just continues. I love to do it. I love people and I love to walk into the store and just mention the candles.”

Father and son hand-pour the candles — they come in 10-ounce and 22-ounce sizes — in small batches, just about “wherever we have to make them,” Michael says with a laugh. The business has grown big enough that they have a warehouse in Warren, New Jersey, but they don’t require a lot of space for production. “

All we need is a hundred square feet to make the candles. I just have a small portion of that warehouse and all you need is a couple of electric outlets and some wax melters and then we have all the materials delivered to us when we need them,” Michael says.

“Just imagine a big, big chowder pot that has a spigot on it, but it’s electric-based,” he adds. “You pour in the soy wax flakes and you set the temperature at whatever you need to set it at, based on the type of wax it is, and you just let it turn to a liquid.”

Once a liquid has formed, they test the wax temperature with a thermometer. “You have to be careful with wax, wax can burn and then it affects the candle so you have to keep it at a certain temperature,” Michael notes.

First, they pour the scent oil mix into the container and then the liquid wax on top of it, before agitating it for a good two minutes “so it flows through” and the scents blend with the wax.

Using a stainless steel pitcher, they pour the wax into the glass containers. It takes about four hours for the candle to cure. Generally, they don’t get put on the shelves for 48 hours.

Like his father, Michael had never envisioned getting into the candle business. “I did not expect to go into this, but it’s been a pleasant surprise,” he says.

“I can say that it’s a very relaxing process and it’s a creative process,” he adds. “Most people don’t think of it, but you have to take the time to do it right and to do it well.”

As for the relaxation part, he says it’s easy “to lose your thoughts for a little while, if you know what I mean. It takes you away from life a little bit for a while, and then before you know it, you’ve made 40 candles.”

Their line also stands out on the market due to its ingredients. “We wanted to do something that was a little bit more sustainable than everybody else,” Michael says.

“Most people don’t know that most candle wax that is used today is petroleum-based,” he explains. “What that means is that when it burns, you see that black soot rising, and that is a byproduct of petroleum.”

They also use recycled glasses. On each is a label, most with drawings that correspond with the unique name, such as two surfboards leaning against an iconic VW van for Ditch Plains Driftwood. Kathleen and Lulu Palmer, a close family friend who works for the company, are the creative forces, and they come up with the designs for new candles. Michael works with art directors who create the final image.

The fragrances are purchased from a supplier by requesting certain levels of different ingredients — obviously they don’t want to give up their percentages.

“We started with really three fragrances,” Michael says, “and now we’re up to, at any given time and during production, we’re up to 25 different fragrances, depending on what customers want.”

The business began just in the retail environment. The Montauk Bake Shop was the first to take in the candles, followed by Strawberry Fields Flowers & Gifts and others. The stores in East Hampton and Amagansett followed. Amber Waves Farm is one of their biggest clients.

“When I was contemplating pricing with my dad about this and with my wife, Kathleen, and we were talking about it, we wanted to make it affordable for the wholesale retailers to buy it from us so they could make money,” Michael says. “We have a very, very affordable candle. I think Amber Waves is selling them for like $10 now. You can’t go into a T.J.Maxx and buy a candle under $15.”

The online business followed when they simply included their website, montaukcandleco.com, on the safety sticker at the bottom of the candles.

“The online business started to take off because people were buying them, leaving at the end of the season, but still wanting to get them,” Michael says. “So that’s a whole different part of the business that has grown from Montauk.”

“In one summer, we went from 300 total candles, which we thought was fantastic, which was obviously a family hobby that turned into, I think, we’re going to do close to 5,000 or 6,000 candles this year,” Michael says.

Montauk Candle Co. is sold throughout the country. “I just got an online order from somebody in Idaho,” Michael says. “I have no idea if they came out to Montauk and they loved it and they ordered it, or they just Googled it.”

Their private label business has also grown. They have been a bit hit in the Hamptons Box subscription service. People can order them in bulk for weddings and the like with the customers designing the labels. “We’re constantly tinkering with fragrances,” says Michael.

“We’re always looking at the latest and greatest in sustainable wax — we just think that’s important.”

This article appeared in the November 2022 edition of Behind The Hedges magazine. Read the full digital edition here. To recommend a Master Craftsman on Long Island or in Palm Beach for a future edition, email TVecsey@danspapers.com.